Warehousing is more than just storage. It’s a core part of how your supply chain works — from how fast you ship to how much you spend. But not all warehouses do the same job. The type of warehousing you choose can directly affect your delivery times, inventory accuracy, and customer satisfaction.

In this guide, we’ll walk you through the different types of warehousing, explain what each one does, and help you decide which fits your business best.

What Are the Types of Warehousing?

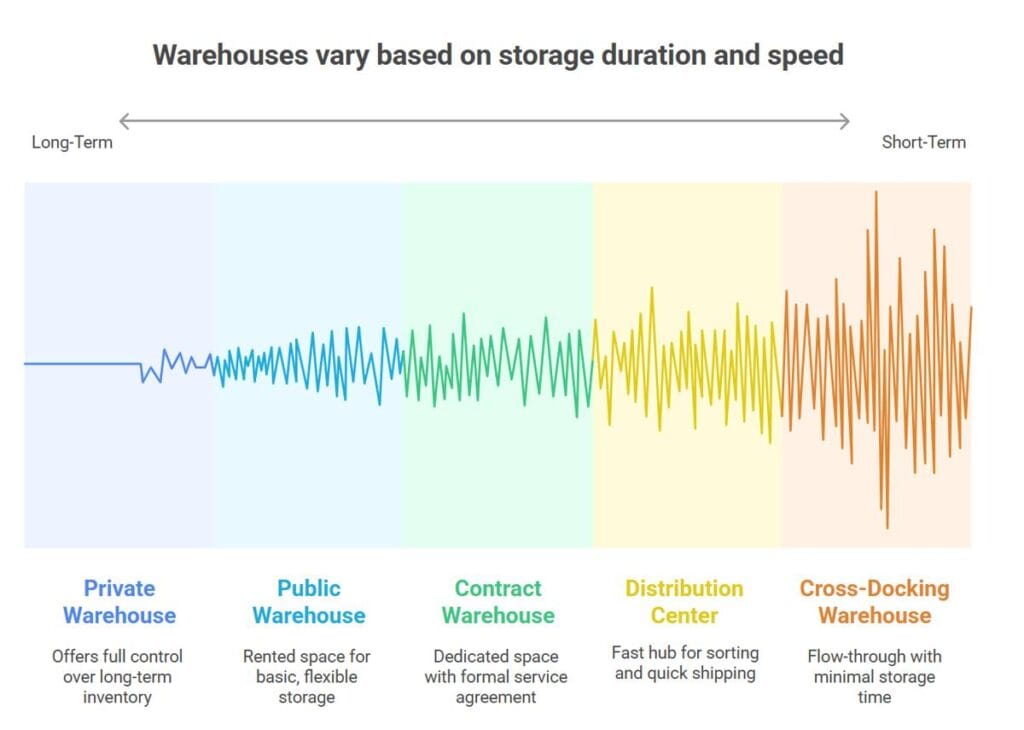

There are several types of warehousing in supply chain management, each with a specific role. Some are built for speed. Some for security. Others for cost savings or cold storage.

Here’s a clear breakdown of the most common types:

1. Private Warehouse

Owned and operated by one business, a private warehouse gives you full control over inventory, layout, and operations.

- Best for: Large businesses with steady inventory needs

- Pros: High control, secure, long-term ROI

- Cons: Expensive to set up and run

2. Public Warehouse

A shared space you can rent short or long-term. It’s run by third-party providers and offers basic storage with optional services.

- Best for: Startups, seasonal businesses

- Pros: Low cost, flexible space

- Cons: Less control, shared resources

3. Bonded Warehouse

Used for storing imported goods before customs duties are paid. Ideal if you need to delay payment until the product sells.

- Best for: Importers, exporters

- Pros: Delays duty payments, secure for international goods

- Cons: Requires government approval and complex compliance

4. Distribution Center

A fast-moving hub where goods arrive, get sorted, and are quickly shipped out. These are built for speed, not long-term storage.

- Best for: Retailers, e-commerce

- Pros: Fast order fulfillment, close to customer zones

- Cons: Not ideal for storing bulk inventory

Read more: Distribution Center vs Warehouse: What’s the Real Difference

5. Fulfillment Center

A type of distribution center, but designed for packing and shipping online orders directly to customers.

- Best for: E-commerce and DTC brands

- Pros: End-to-end order handling, includes returns

- Cons: Less visibility and control over packaging and speed

6. Cold Storage Warehouse

Keeps products at low or specific temperatures. Perfect for items that spoil, melt, or degrade in regular storage.

- Best for: Food, pharmaceuticals, flowers

- Pros: Preserves product quality

- Cons: High operating costs

7. Smart Warehouse

These are tech-driven spaces with robots, sensors, and automation that reduce labor and speed up tasks like picking and sorting.

- Best for: High-volume businesses

- Pros: Fast, accurate, low labor need

- Cons: Expensive to build and maintain

8. Contract Warehouse

A third-party facility you rent with a formal agreement. You get dedicated space and services without owning the building.

- Best for: Mid-sized businesses needing reliability

- Pros: More control than public warehouses

- Cons: Long-term contract required

9. Cooperative Warehouse

Owned and used by multiple businesses (often co-ops). Costs are shared and profits aren’t the goal.

- Best for: Farmers, small producers, local brands

- Pros: Affordable, supportive model

- Cons: Limited to co-op members

10. Cross-Docking Warehouse

A flow-through warehouse. Goods come in and go out quickly with little or no storage in between.

- Best for: Retailers with high turnover

- Pros: Saves time, cuts storage costs

- Cons: Not ideal if inventory stays long

11. Reverse Logistics Warehouse

Handles returns, repairs, or recycling. Helps manage what happens when a product comes back.

- Best for: E-commerce, electronics, warranty items

- Pros: Saves value from returns

- Cons: Complex to manage

12. Hazmat Warehouse

Built for hazardous materials like chemicals, flammables, or radioactive goods. Has strict legal and safety requirements.

- Best for: Chemical and medical industries

- Pros: Meets legal storage needs

- Cons: Expensive and highly regulated

13. Buffer or Interim Warehouses

Used for short-term overflow or when shifting between stages of production. Often located near factories.

- Best for: Manufacturers, growing businesses

- Pros: Prevents delays, supports just-in-time models

- Cons: Temporary solution

3 Types of Warehousing Every Business Should Know

If you’re just starting, these three types of warehousing are the most common:

- Public Warehouse – Rentable, shared storage

- Private Warehouse – Fully owned and operated by one company

- Distribution Center – Fast-moving, short-term storage for shipping

These cover most needs for small to mid-sized businesses. As you grow, you may need more specialized setups like cold storage or fulfillment centers.

How to Choose the Right Warehouse

Ask yourself these questions:

- Do I need long-term or short-term storage?

- Do my products need temperature control?

- Will I handle shipping myself or use a fulfillment service?

- How fast do I need to process orders?

- Do I need to manage imports and customs?

If you’re selling perishable items, go cold. If you sell online, use fulfillment. If you’re importing, bonded might be your answer.

Why Warehousing Matters in Supply Chain Management

The types of warehousing in supply chain management you choose directly affect:

- Speed of delivery

- Inventory accuracy

- Shipping costs

- Customer satisfaction

Choosing the wrong type slows you down. Choosing the right one lets you scale faster, ship smarter, and keep costs low.

Final Thoughts

So, what are the types of warehousing? They’re more than buildings. Each one serves a role — and choosing the right fit can help you stay competitive, efficient, and profitable.

Whether you need simple storage or high-speed fulfillment, there’s a warehousing type built for you.

Want to build a smarter supply chain? Start by picking the right warehouse.

FAQs

1. What are the 7s of warehousing?

The 7s of warehousing refer to the key principles that guide efficient warehouse operations:

- Structure – The physical design/layout of the warehouse

- Space – Optimal use of available storage area

- Staff – Skilled labor to manage warehouse tasks

- System – Technology and processes for inventory and order tracking

- Standards – Safety, quality, and compliance guidelines

- Security – Protection from theft, damage, or loss

- Sustainability – Energy use, waste reduction, and eco-friendly practices

These help improve productivity, reduce costs, and keep the warehouse running smoothly.

2. What are the seven functions of warehousing?

The seven core functions of warehousing include:

- Storage – Holding goods until they’re needed

- Inventory Management – Tracking stock levels and movement

- Order Picking and Packing – Preparing goods for shipment

- Shipping – Sending products to their next destination

- Returns Handling – Managing reverse logistics or returned items

- Risk Minimization – Protecting goods from damage or theft

- Value-Added Services – Includes labeling, kitting, grading, or assembling

Each function plays a role in making supply chains more reliable and responsive.

3. What are the 8 types of logistics?

The 8 types of logistics describe how goods, services, and information move within and across businesses:

- Inbound Logistics – Moving raw materials into a business

- Outbound Logistics – Shipping finished products to customers

- Procurement Logistics – Handling orders and supply deliveries

- Production Logistics – Coordinating movement within manufacturing

- Sales Logistics – Managing delivery to end users or retailers

- Recovery Logistics – Handling returns, repairs, and recycling

- Distribution Logistics – Moving goods to warehouses or retail

- Reverse Logistics – Processing product returns or replacements

Together, these cover the full lifecycle of a product, from sourcing to post-sale handling.

4. Can a warehouse be both public and private?

Not usually. A public warehouse serves multiple businesses, while a private warehouse is used by one company only. However, some large private warehouses rent out extra space, acting like both.